Fascination About Aws Cwi

Fascination About Aws Cwi

Blog Article

Aws Cwi Fundamentals Explained

Table of ContentsRumored Buzz on Aws CwiAn Unbiased View of Aws CwiAws Cwi for Beginners5 Easy Facts About Aws Cwi DescribedAws Cwi Can Be Fun For Anyone

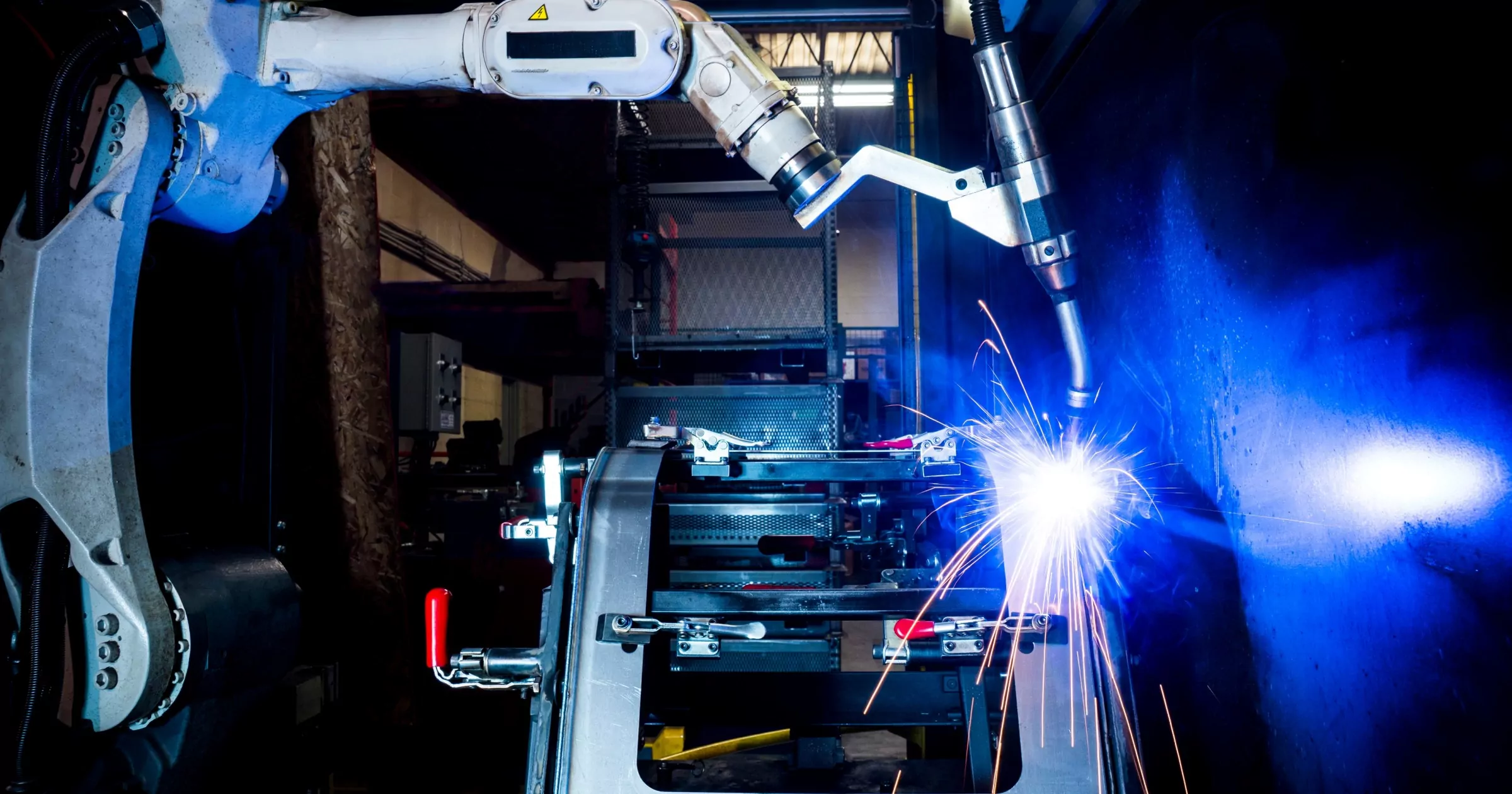

Third-party quality control assessment of steel fabrication fixate welding inspection, as well as examination of bolting and painting of architectural steel. KTA's steel assessors supply Quality assurance (QC) examiners to supplement fabricator's/ specialist's in-house QC staff and on projects that mandate keeping the solutions of a qualified examiner (e.g., CWI) utilized by an independent evaluation firm.Inspectors perform visual inspections of product for uniformity with the approved specs, plans and codes, as well as verification of Licensed Material Test Records (CMTR) for materials used. Products and components are observed at bottom lines along the production process in both steel mills and steel fabrication stores. KTA's licensed welding examiners additionally witness welder and welding procedure qualification examinations as suitable to the extent of the task.

Steel construction inspection solutions likewise regularly consist of performing non-destructive testing (NDT), also understood as non-destructive examination (NDE), consisting of Magnetic Bit Evaluating (MT), Ultrasonic Screening (UT) and Liquid Penetrant Checking (PT). KTA's evaluation solutions include finishing inspections covering surface prep work, painting, galvanizing, and metalizing.

KTA's viewpoint is to react rapidly to clients' requirements, match the right inspector to the work, and give the requisite documents. KTA has the support employees to give technological consulting to the field workers and to the customer. KTA has professionals offered to seek advice from on welding, NDT and layers.

Come sign up with a remarkable group in an interesting, quick paced, and ever-growing industry! We are seeking a CWI's and/or NDT Degree II certified Welding Inspectors from in and around the Lithia Springs, GA area!

Indicators on Aws Cwi You Should Know

Suitable prospect will certainly have high purity piping evaluation experience. CWI's and NDT Degree II's highly encouraged to apply.

Pro QC's third-party welding assessment solutions include: Paper Testimonial Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding assessment records are provided within 24-hour and document all examination points relevant to high quality, consisting of all identified weld flaws and electronic images (Certified Welding Inspection) (https://www.pinterest.com/pin/982136631350953777). Pro QC's team of assessors delivers third-party welding inspections around the world, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and lots of view website even more countries

Assessment of the welding work is critical for proper top quality When your firm is taking care of major projects with demands for 3rd event independent welding examination, we provide outstanding welding witness inspection solutions to validate that welding has been performed according to most applied welding criteria and specs. AQSS performs welding examination services for clients from a variety of markets.

The 7-Second Trick For Aws Cwi

Not following correctly qualified welding procedures often causes a weld of poor high quality, which can enhance the construction's possibility of failing under designated service conditions. By inspecting for flaws, our examiners can assist clients guarantee that their welds satisfy appropriate requirements of quality control (Welding Inspection Agency). Weld inspections are carried out for several factors, one of the most typical of which is to identify whether the weld is of suitable high quality for its intended application

The code and basic used depends on the market. Our welding examiners have the required accreditations with years of experience with evaluation and know with a lot of used welding standards and specs. AQSS has actually CWI accredited inspectors. We execute these services utilizing a range of nondestructive testing (NDT) techniques: The inspection is executed in accordance with appropriate codes, such as American Welding Society (AWS), American Culture of Mechanical Engineers (ASME), and Armed Forces (MIL-STD) conventional specs.

What Does Aws Cwi Do?

Commonly, our assessors are checking for cracks, pits, surface area pores, undercut, underfill, missed out on joints, and various other aspects of the weld.

Examples can also be taken at intervals during the manufacturing process or at the end of the run. Devastating testing examples are specifically reduced, machined, ground, and polished to a mirror-like surface. An acid etch is after that related to aesthetically draw out the weld, and the sample is then examined under a microscope.

Report this page